介绍 summary

The MGC7000 series is my company impact type special governor series, our company in this series has a unique combination of CO injection needle control module, Pelton turbine speed control system is generally the needle all in a fixed order, in accordance with the power unit needed a control needle opening and closing control, independent needle not allowed.

MGC7000 is a series of procedures can be used to achieve multi needle coordination control allows needle be adjusted independently while maintaining the optimal efficiency of the unit, and the needle sorting automatically change according to the working state of the injection needle, greatly optimized regulation performance, simplifies the mechanical control system. The joint control (sorting) module controls the injection needle that is put into operation.

It is suitable for all series impact units

-

Single and double controller

-

Small, medium, large, super large series of impact governor

-

Multi nozzle independent control and synchronization technology

-

Steering cooperative control

-

The utility model has the advantages of simple structure, convenient disassembly and maintenance

-

Reliable operation and little noise

-

Digital valve or proportional valve control system

-

Electromechanical cabinet or electromechanical cabinet

外形尺寸图 Dimenensions

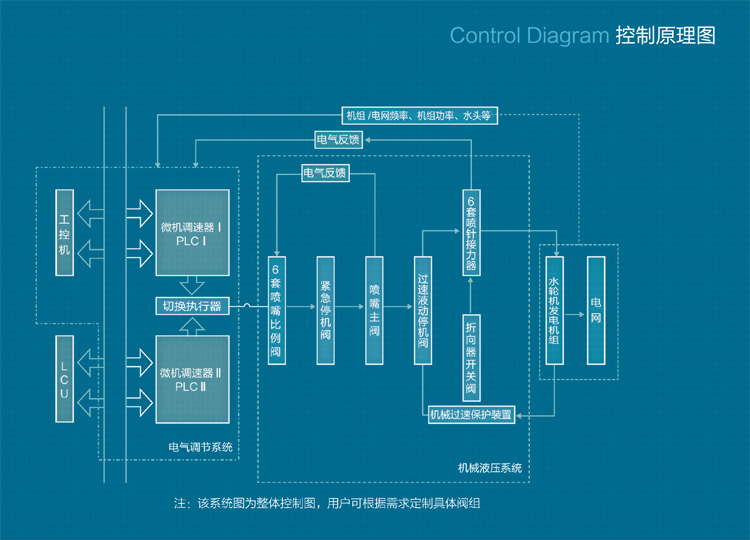

控制原理图 Control diagram

技术参数 Technical Parameter

|

技术参数 Specifications

|

技术指标 Technical Data

|

|

Cabinet characteristics

|

|

Dimension of cabinet of electromechanical joint cabinet

|

800mm*800mm*1860mm(length * width * height) can be customized

|

|

Electromechanical cabinet, electric cabinet size

|

600mm*800mm*2260mm or 800mm*800mm*2260mm (length * width * height)

|

|

Cabinet weight

|

300kg

|

|

AC voltage standard for work

|

AC220V±15%

|

|

Operating DC voltage standard

|

DC110V±10%,DC220V±15%

|

|

Load capacity

|

2200W(VA)

|

|

Withstand voltage test

|

1.5kV,1min

|

|

Protection level

|

IP65

|

|

Operating temperature range

|

-40~65℃

|

|

Insulation impedance

|

>10MΩ

|

|

leakage current

|

<1mA

|

|

Control signal output

|

|

servo motor

|

Servo motor drive outlet

|

|

Proportional valve

|

The analog channel current is 4 to 20mA

|

|

Input characteristic

|

|

Switch input

|

DC24V, LED indicator, full isolation

|

|

Analog input

|

Voltage 0 ~ 10V, current 4 ~ 20mA, LED indicator light, completely isolated

|

|

output characteristic

|

|

On-off output

|

DC24V, LED indicator, full isolation

|

|

Analog output

|

Voltage 0 ~ 10V, current 4 ~ 20mA, LED indicator light, completely isolated

|

|

Frequency measurement specification

|

|

Measurement mode

|

Controller body frequency measurement

|

|

Grid frequency

|

Alternating current (30 ~ 150V), rated frequency of 90 to 110%

|

|

Unit frequency

|

Alternating current (0.3 ~ 150V), 7.8 to 110 Hz

|

|

Frequency measurement of gear disc

|

Contactless proximity switch (DC24V power supply) 1~110 Hz

|

|

Frequency measuring resolution

|

0.001Hz

|

|

Frequency measuring channel

|

Unit residual pressure frequency, system frequency, unit gear speed measurement

|

|

|

性能参数 performance parameter

|

性能参数 Specifications

|

技术指标 Technical Data

|

|

Stability performance

|

|

Relative value of unit speed swing

|

<±0.15%

|

|

Gateopening stable fluctuation value

|

<0.1%

|

|

Maximum nonlinearity of static characteristic curve

|

<0.3%

|

|

Speed dead zone

|

<0.02%

|

|

Dynamic characteristics

|

|

Load wave crest not exceeding

|

2 times

|

|

Ratio of load rejection unit (tE) to (tM)

|

<12

|

|

Minimum relative speed of load rejection

|

>90%

|

|

(tSR) and (t0.8) ratios

|

<5

|

|

servomotor dead time

|

<0.2s

|

|

Power generation automatic turn on time

|

20~120s Can set

|

|

Parameter setting of speed regulation system

|

|

The adjustment range of the permanent slip coefficient is

|

0~10%

|

|

Slip adjustment range is

|

0~10%

|

|

Adjust the frequency range of the manual frequency on line

|

0~±1.5%

|

|

Speed adjustment range is

|

90~110%

|

|

The power adjustment range is

|

0~105%

|

|

Zero load and full load adjustment time

|

20~300s

|

|

Mode of operation, switching, relay changes

|

<0.3%

|

|

Dual power switching relay changes

|

<0.1%

|

|

Dual controller switching relay changes

|

<0.1%

|

|

Proportional gain Kp range

|

0~20

|

|

Integral gain Ki range

|

0.01~10(1/s)

|

|

Differential gain Kd range

|

0.01~10s

|

|

The speed regulation system can be utilized not less than

|

99.99%

|

|

The first trouble free interval is not less than

|

30000

|

|

|

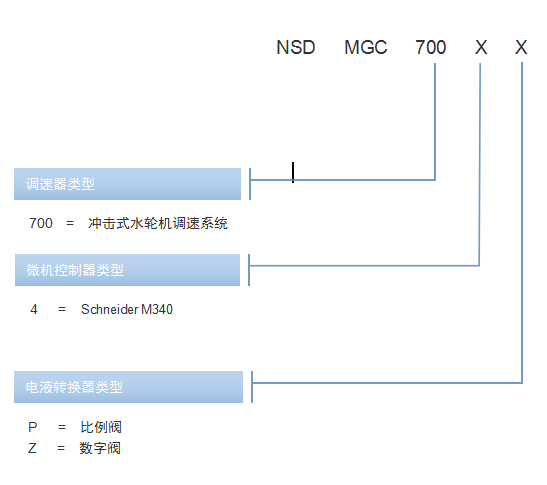

选型表 Model code